How much does 3d printing cost? - A Technical Report:

Additive manufacturing or 3D printing is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes. 3D printing is considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes).

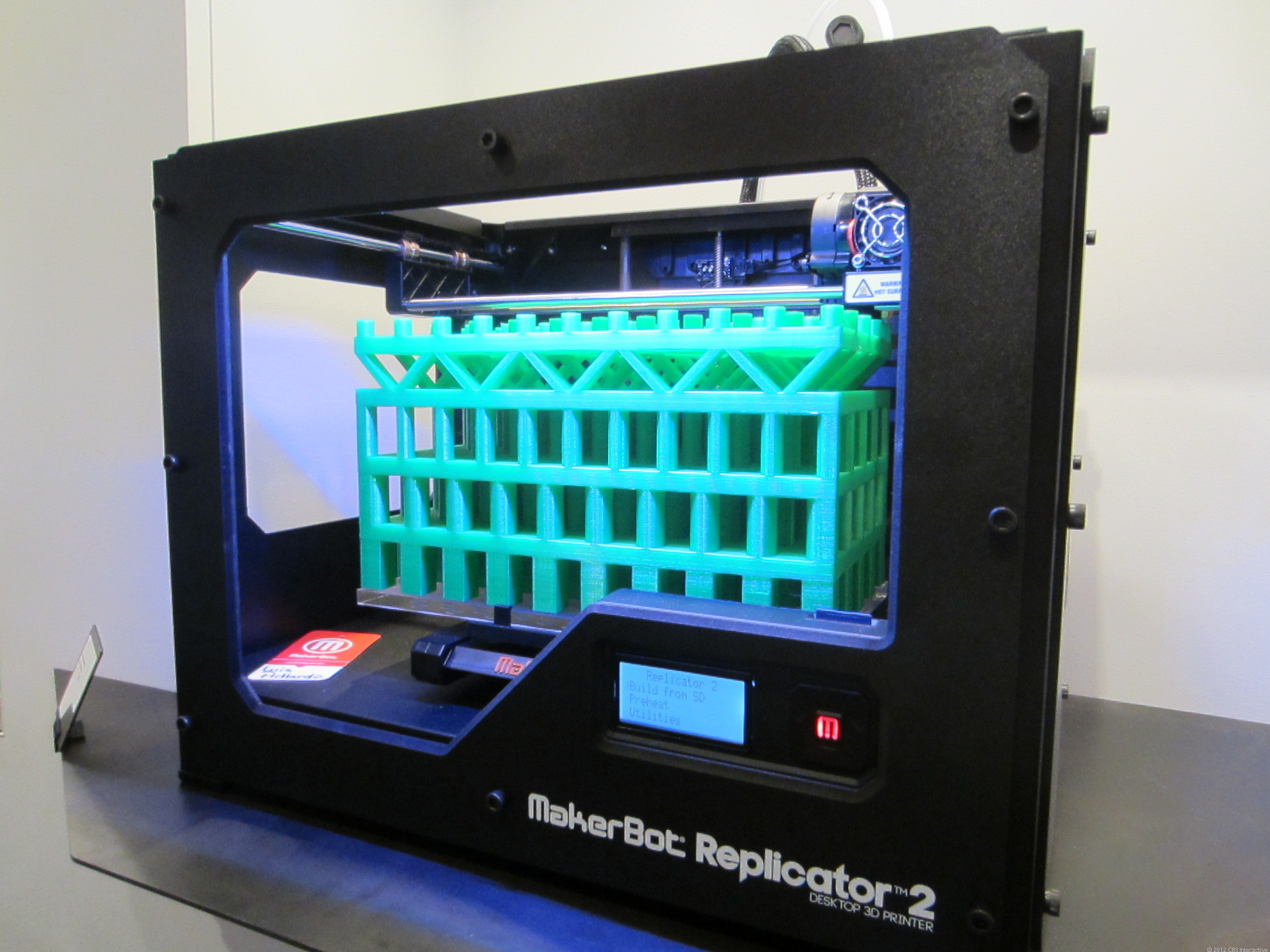

A materials printer usually performs 3D printing processes using digital technology. Since the start of the twenty-first century there has been a large growth in the sales of these machines, and their price has dropped substantially.

The technology is used for both prototyping and distributed manufacturing in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, and many other fields.

Charles Hull is the inventor of the modern 3D printer and originator of de facto standard technologies.[citation needed] The first published account of a printed solid model was made in 1981 by Hideo Kodama of Nagoya Municipal Industrial Research Institute. The technology has improved substantially since that first published account.

The term additive manufacturing refers to technologies that create objects through a sequential layering process. Objects that are manufactured additively can be used anywhere throughout the product life cycle, from pre-production to full-scale production (i.e. rapid manufacturing), in addition to tooling applications and post-production customization.

In manufacturing, and machining in particular, subtractive methods are typically coined as traditional methods. The very term subtractive manufacturing is a retronym developed in recent years to distinguish it from newer additive manufacturing techniques. Although fabrication has included methods that are essentially "additive" for centuries (such as joining plates, sheets, forgings, and rolled work via riveting, screwing, forge welding, or newer kinds of welding), it did not include the information technology component of model-based definition. Machining (generating exact shapes with high precision) has typically been subtractive, from filing and turning to milling and grinding.

General principles:

3D model slicing

Modeling

Additive manufacturing takes virtual blueprints from computer aided design (CAD) or animation modeling software and "slices" them into digital cross-sections for the machine to successively use as a guideline for printing. Depending on the machine used, material or a binding material is deposited on the build bed or platform until material/binder layering is complete and the final 3D model has been "printed." It is a WYSIWYG process where the virtual model and the physical model are almost identical.

A standard data interface between CAD software and the machines is the STL file format. An STL file approximates the shape of a part or assembly using triangular facets. Smaller facets produce a higher quality surface. PLY is a scanner generated input file format, and VRML (or WRL) files are often used as input for 3D printing technologies that are able to print in full color.

Printing

To perform a print, the machine reads the design from an .stl file and lays down successive layers of liquid, powder, paper or sheet material to build the model from a series of cross sections. These layers, which correspond to the virtual cross sections from the CAD model, are joined together or automatically fused to create the final shape. The primary advantage of this technique is its ability to create almost any shape or geometric feature.

Printer resolution describes layer thickness and X-Y resolution in dpi (dots per inch), or micrometres. Typical layer thickness is around 100 micrometres (0.1 mm), although some machines such as the Objet Connex series and 3D Systems' ProJet series can print layers as thin as 16 micrometres. X-Y resolution is comparable to that of laser printers. The particles (3D dots) are around 50 to 100 micrometres (0.05–0.1 mm) in diameter.

Construction of a model with contemporary methods can take anywhere from several hours to several days, depending on the method used and the size and complexity of the model. Additive systems can typically reduce this time to a few hours, although it varies widely depending on the type of machine used and the size and number of models being produced simultaneously.

Traditional techniques like injection molding can be less expensive for manufacturing polymer products in high quantities, but additive manufacturing can be faster, more flexible and less expensive when producing relatively small quantities of parts. 3D printers give designers and concept development teams the ability to produce parts and concept models using a desktop size printer.

Finishing:

Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution, and then removing material with a higher-resolution subtractive process can achieve greater precision.

Some additive manufacturing techniques are capable of using multiple materials in the course of constructing parts. Some are able to print in multiple colors and color combinations simultaneously. Some also utilize supports when building. Supports are removable or dissolvable upon completion of the print, and are used to support overhanging features during construction.

Additive processes:

Rapid prototyping worldwide

The Audi RSQ was made with rapid prototyping industrial KUKA robots

Several different 3D printing processes have been invented since the late 1970s. The printers were originally large, expensive, and highly limited in what they could produce.

A number of additive processes are now available. They differ in the way layers are deposited to create parts and in the materials that can be used. Some methods melt or soften material to produce the layers, e.g. selective laser sintering (SLS) and fused deposition modeling (FDM), while others cure liquid materials using different sophisticated technologies, e.g. stereolithography (SLA). With laminated object manufacturing (LOM), thin layers are cut to shape and joined together (e.g. paper, polymer, metal). Each method has its own advantages and drawbacks, and some companies consequently offer a choice between powder and polymer for the material from which the object is built. Some companies use standard, off-the-shelf business paper as the build material to produce a durable prototype. The main considerations in choosing a machine are generally speed, cost of the 3D printer, cost of the printed prototype, and cost and choice of materials and color capabilities.

Printers that work directly with metals are expensive. In some cases, however, less expensive printers can be used to make a mould, which is then used to make metal parts.

How much does 3d printing cost?

According to Pete Basiliere, research director at Gartner, an American information technology research and advisory firm, "At present, 3D printing is a technology accelerating to mainstream adoption." And he goes on to argue that it is already "affordable to most enterprises."

Affordable to enterprises, however, does not mean affordable to everyone. Yet while 3D printing technology is currently out of the price range of most people, this will quickly change as the technology becomes more widespread. And it already is becoming more affordable and accessible.

In an article for Tech Crunch in March, Matt Burns argued that the "current cost of 3D printing relegates it to the well-off hobbyist or successful small businesses." According to the report by Gartner, enterprise-class 3D printers will cost less than $2,000 by 2016. For enterprise printers, Burns says, "read: 3D printers not made by hipsters in Brooklyn."

But while 3D printers are still out of reach for most people, this is changing. Jonathan Fincher of Gizmag writes that until now 3D printers were limited to purchase through "specialist stores and online shops" and that you couldn't just "waltz into your local office supply store and pick one up along with a pack of manila folders and paperclips." But soon you will be able to. Office supply chain Staples recently announced that it is now selling 3D printers, specifically the Cube 3D Printer from 3D Systems (see below), through its website and that they will be available in selected stores by the end of the month. The Cube 3D "comes fully assembled right out of the box, takes up relatively little space on a desktop, and installs easily on Mac and Windows computers. It's capable of printing items up to 5.5 x 5.5 x 5.5 inches (14 x 14 x 14 cm) in 16 different colors" and currently costs $1299.99.

Refer to: http://en.wikipedia.org/wiki/3D_printing / http://www.policymic.com/articles/41111/how-much-does-a-3d-printer-cost-still-expensive-but-becoming-more-affordable

Edited by Kevin from Xiamen Romandy Art Limited.

(Xiamen Romandy Art is a professional oil paintings supplier from China. If you want to convert your photos into high quality oil paintings, or you want the masterpiece oil painting reproductions, please don's hesitate to contact with us.)

Romandy Art Website: http://www.oilpaintingcentre.com

Tags: How much does 3d printing cost? 3d printing service cost, cost of 3D printing.

|